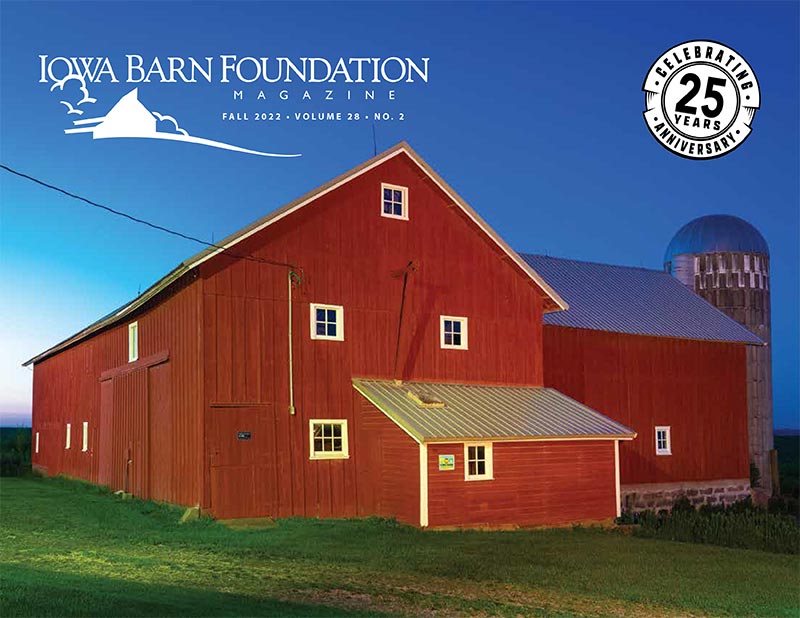

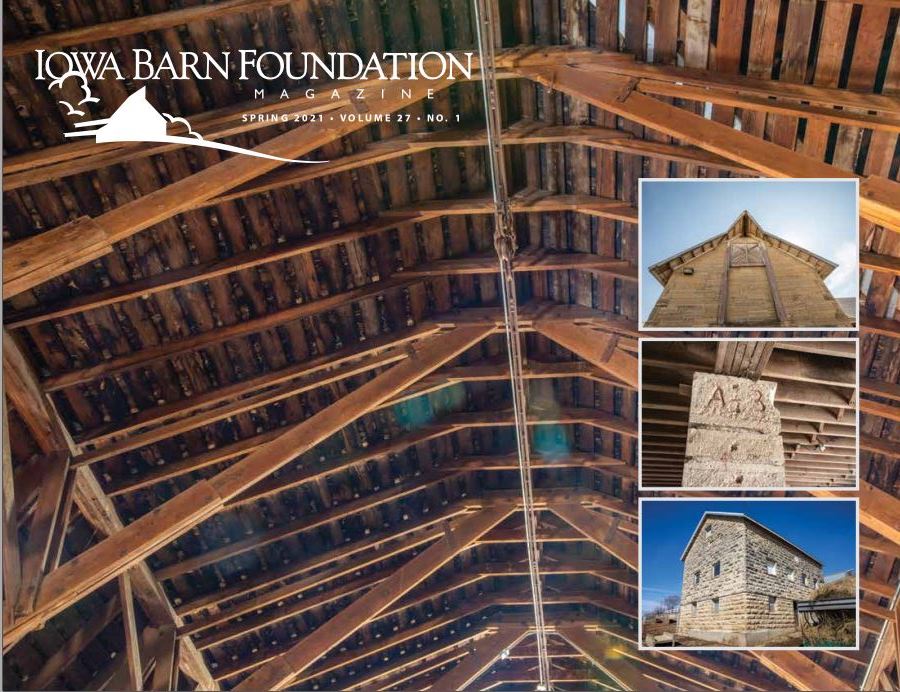

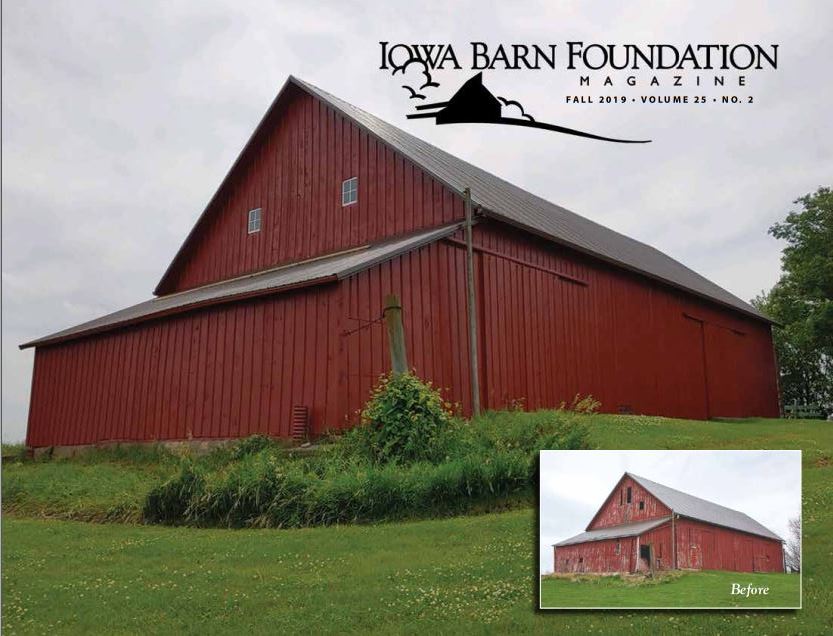

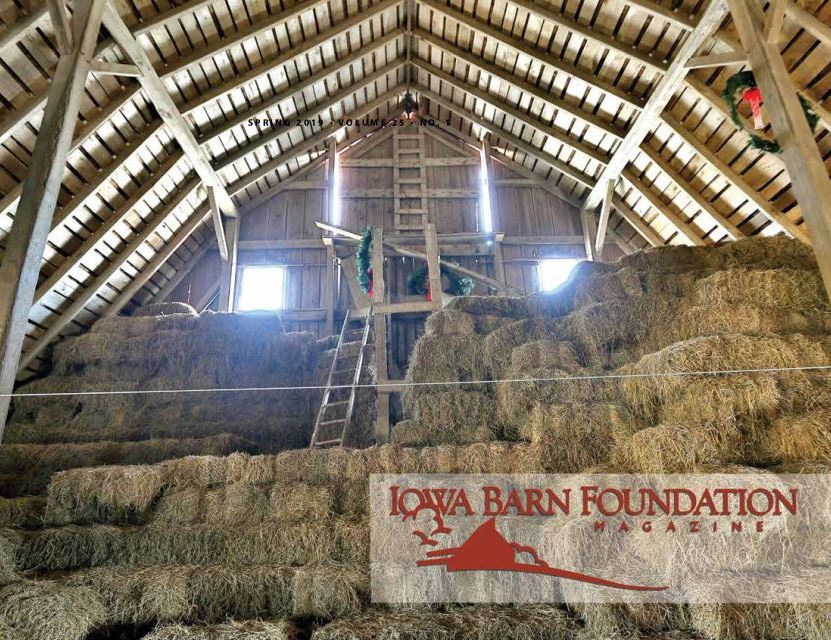

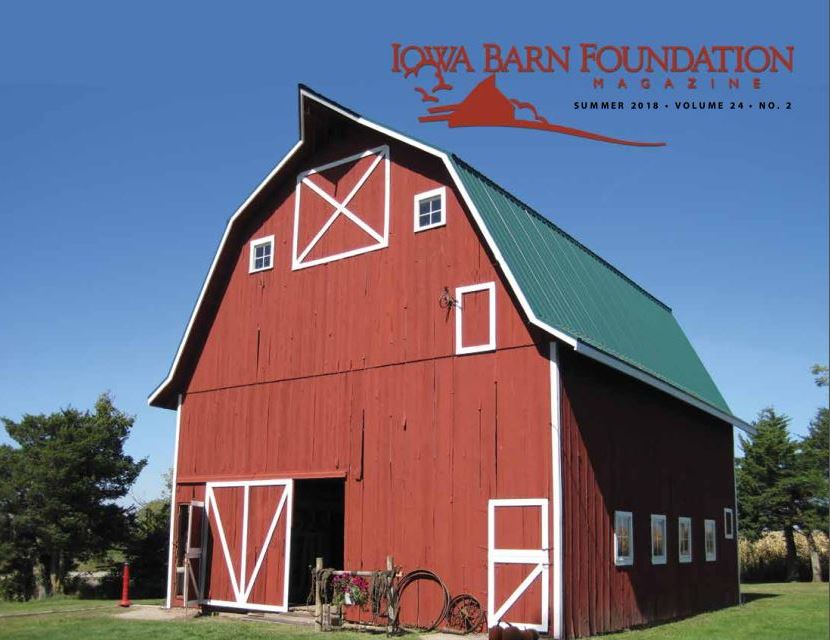

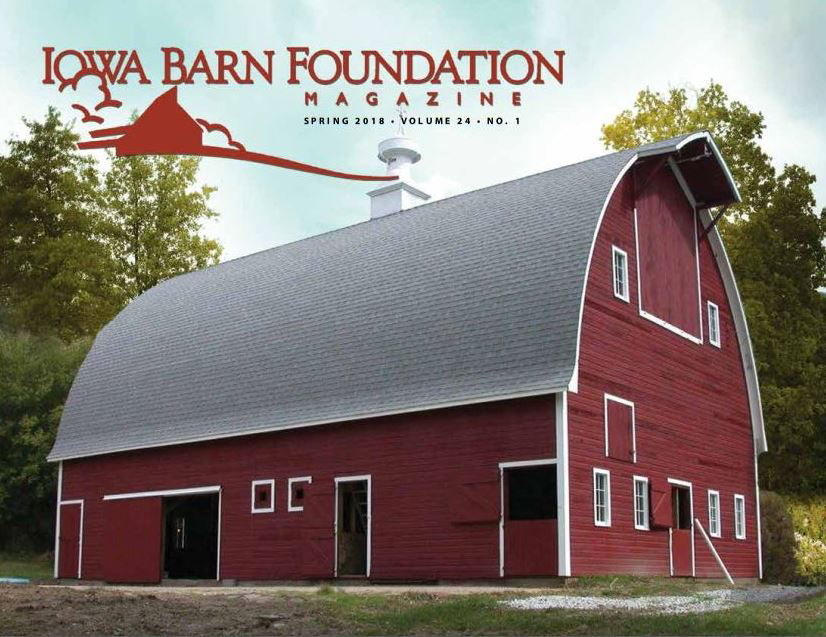

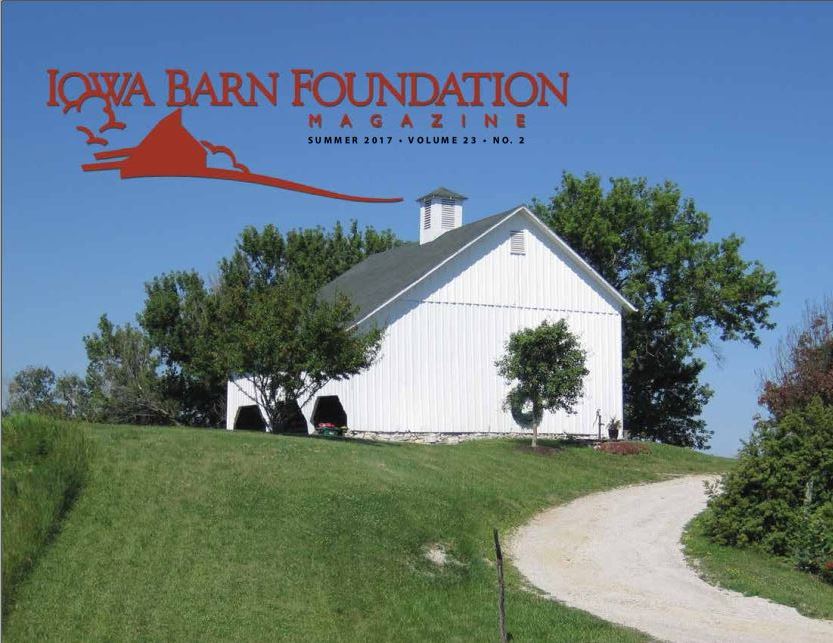

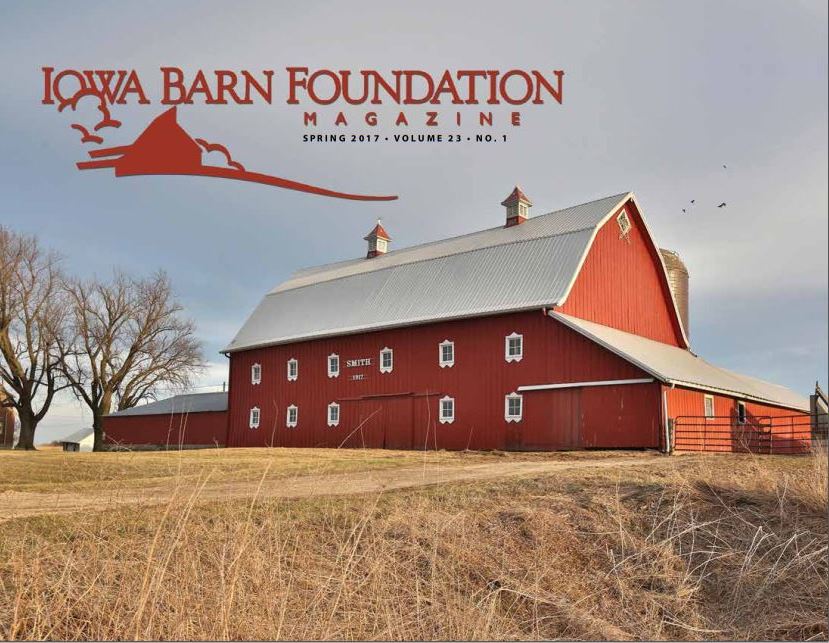

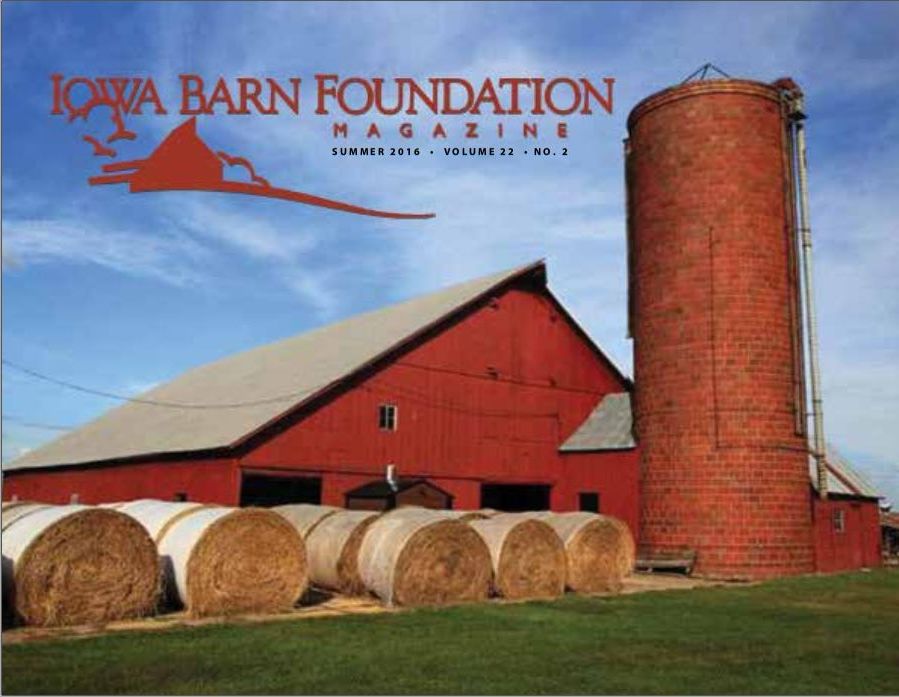

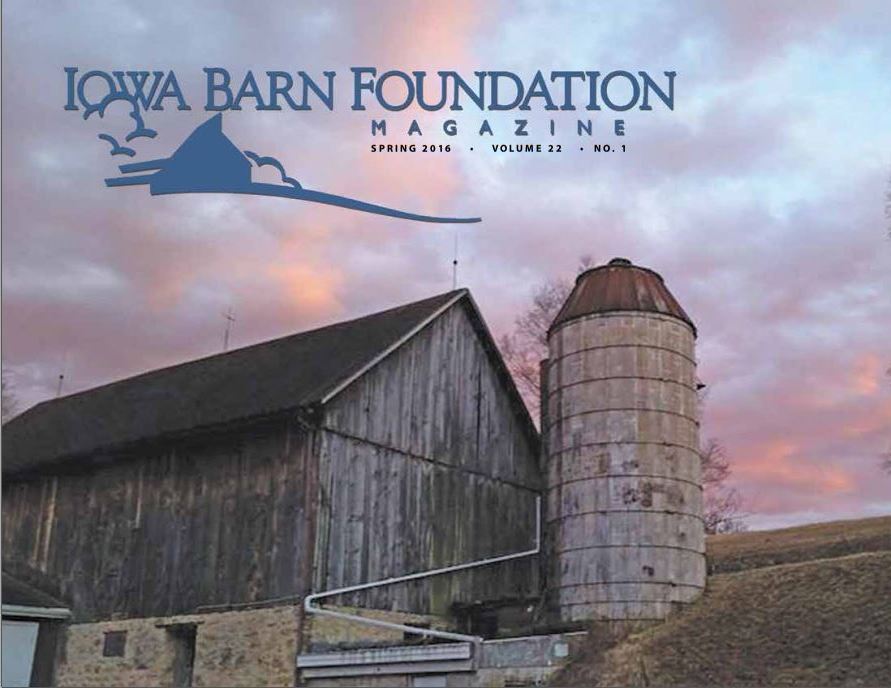

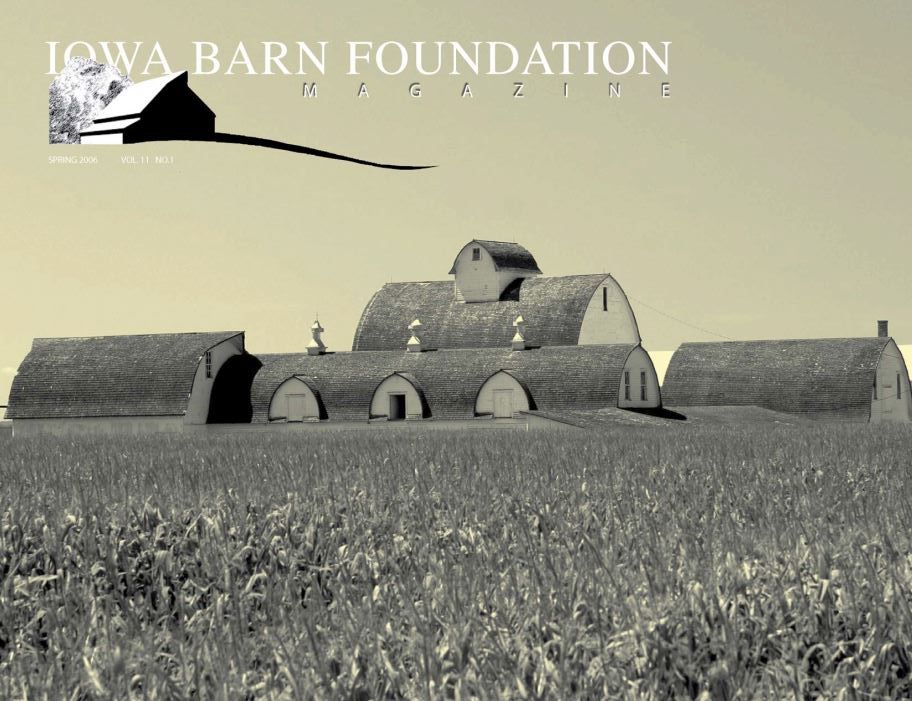

Our member donors receive our magazine in their mailboxes twice a year. In addition to articles on barn history and preservation efforts, the magazine includes our spring and fall barn tour guides to help you plan your trips. Please see below to view past editions.